Insights on driving value from staffing, automation and continuous improvement.

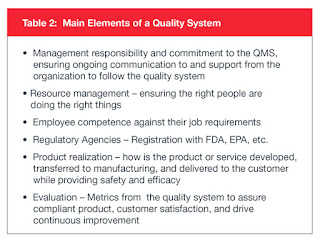

Developing a quality management system is the foundation for ensuring the organization’s products or services are safe, effective and controlled to deliver customer satisfaction. Throughout the organization’s lifecycle, from start-up through maturity, the quality needs of the firm, along with its budget constraints, are continually evolving. Maintaining compliance with regulations while controlling costs represents a challenging balancing act we encounter in our life science consultancy. The most successful firms apply critical assessment of their needs and gaps at present and in the future, and deploy a risk-based approach to their quality system.

Upfront Planning Avoids Costly Surprises

Before establishing a quality system, it’s critical to identify the quality standards, regulations and/or requirements surrounding the company’s products, service and business needs. The checklist in Table 1 provides some common areas to consider.

Gap Analysis

If your organization already has a quality system, perform a gap analysis against your identified standards/requirements per Table 1. If your quality team could benefit from an external assessment, consider hiring an experienced consultant or firm to provide expertise in the gap analysis.

ISO13485

If your organization is or will be manufacturing or distributing internationally, global considerations will add complexity to your quality system. For example, the following considerations can greatly impact the complexity of the quality system; European Union, ISO13485, Canadian Medical Devices Regulations, Brazilian GMP, and Japanese Ordinance #169, and others.

Phased Enhancements: Spread the Spend Over Time

Maximizing Value from Staffing

- Quality System Leader The organization requires a competent and knowledgeable individual as the quality system leader(s) who may implement the QMS, keep the system compliant, and maintain the design history file.

- Based on the lifecycle of the organization, the quality system leader may be tasked with implementing the QMS or just maintaining the QMS going forward. This could be two different skill sets.

- Tip: Early stage companies can benefit from outsourcing development of the QMS to highly experienced quality consultants and then transition maintenance of the QMS to less expensive in-house personnel.

- Skill Assessment By analyzing the skill sets of in-house quality personnel against needs, firms can identify gaps and develop solutions. A few considerations:

- Tip: Can current staff be trained? Training represents an upfront cost but offers long- term payoff.

Training Programs

- Utilize assessments and audits to understand the capabilities ceiling of your existing team. If training cannot close the critical gaps, consider whether the needed skill set is temporary or long-term. Temporary gaps can be closed cost effectively through hiring of contractors or DHF consultants to provide specialized knowledge without paying for a full-time employee. Such expertise can be used for:

Maximizing Value from Automation

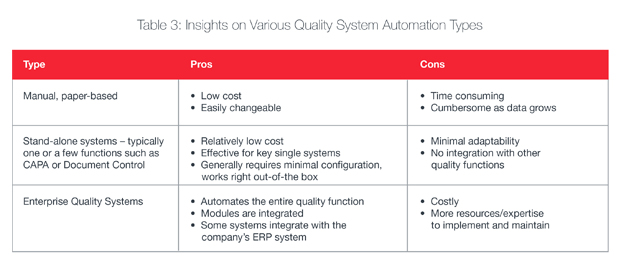

- Start-up or early stage organizations can benefit from basic manual systems or hybrid systems that automate some of the more labor-intensive quality functions such as document control.

- Mid-market organizations can benefit from increased automation through hybrid or enterprise QMS systems that address multiple quality needs such as document control, deviations control, non-conformance, equipment calibration, equipment maintenance orders, audit, CAPA, change control, training and functions that control product outputs.

- Large organizations can benefit from enterprise QMS systems and integrating those systems with their ERP systems for even greater interoperability.

Maximizing Value from Continuous Improvement

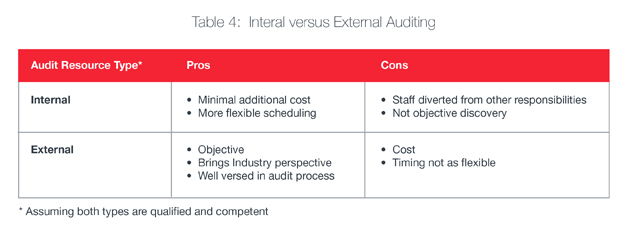

- Internal and external audits program

- Complaints

- Customer feedback

- CAPA system

- Product or process non-conformances

- Processing data

- Enforcement activity such as a FDA 483 or Warning Letter

- Costs relative to the budget

- Concerns about cybersecurity and cost

Budget Maximizing Tips

Travel:

- Limiting travel by employees and choosing local contractors or consultants to minimize this expense.

- For organizations with multiple locations, consider leveraging the geography of the company’s quality personnel. For example, if facility A has an out-of-state supplier located near sister facility B, then facility A might be able to tap into the facility B personnel to perform the supplier audit. The travel savings could offset the cost to quality facility B personnel on the QMS audit.

Training:

- Delaying training can minimize this expense. Although it can be less expensive in the long run to raise the skill set of your employees in areas such as internal audits, some companies trim budgets by foregoing to deferring training.

- Virtual cGMP training is another possibility to minimize training expense. By training all your employees at once, companies can negotiate reduced training fees and may possibly eliminate department travel by having a trainer come onsite to the company.

- Delaying supplier audits Sometimes audits can be scheduled to the next quarter or early next year to save expense based on the acceptable risk exposure.

- Group input: The quality team is the cornerstone of the QMS. Engaging these internal experts can identify creative opportunities to trim expenses while minimizing risk.

Today’s Quality leaders are responsible for managing the organization’s compliance and cost of quality, while driving customer satisfaction and maximizing their department budgets. Careful planning and judicious use of human capital and other resources are critical in deploying a risk-based strategy that delivers organizational results.

About RCA’s Medical Device Consulting Services

The regulatory compliance process surrounding the medical device industry involves a strict adherence to pre/post market information throughout a device’s life cycle. Even a single compliance issue you have can turn into a significant effect on your business. Regulatory Compliance Associates can help guide you through any stage of the medical device consulting process, with capabilities during product development through the regulatory clearance/approval of your product.

Our team of over 500 medical device consulting Experts — including former FDA officials and regulatory compliance leaders in the field of medical device regulation — will work with your company to create a quality assurance and regulatory compliance approach tailored to your products and regulatory needs. Regulatory Compliance Associates works with international Fortune 100 companies, venture capital start ups, and companies of all sizes and shapes. Our regulatory compliance solutions for law firms include remediation for warning letters, FDA 483’s, import bans or consent decrees. Very few regulatory compliance services have the same regulatory compliance expertise in a variety of medical fields.

Medical Device Cybersecurity

For medical device manufacturers, technology can be a double-edged sword. The innovative technologies that elevate the quality of life for patients can also be used to potentially undermine the organization using the device. The consequences can affect the device itself if Regulatory Compliance Associates medtech consultants do not implement good IoT cybersecurity and FDA cybersecurity protocols.

At Regulatory Compliance Associates, we offer a wide variety of services for medical devices security to help ensure that your product is protected from cyber-attacks. With a well-planned design, along with full visibility of product development and the supply chain, Regulatory Compliance Associates medical device consultant Experts can help strengthen your device’s cybersecurity. We partner with medical device companies in each phase of the design cycle. The RCA medical device consulting team understands protecting inputs from threat exposure and hardening outputs for regulatory compliance & FDA submission approval.

- SaMD Consulting

- Threat Modeling

- Proof of Concept

- Quality Assurance Services

- TIR 57 & TIR 97

- ISO 62304

- ISO 27001

Regulatory Affairs

Regulatory affairs is Regulatory Compliance Associates® backbone. We handle more regulatory consulting submissions in a month than many manufacturers do in a lifetime. Our regulatory compliance consulting Experts have experience working with the FDA, global regulatory bodies and / or agencies, and notified bodies worldwide. Therefore, you can count on us for in-depth and up-to-date insights which increase speed-to-market.

As a trusted regulatory affairs consultant, our FDA veterans and regulatory consulting team represents Regulatory Compliance Associates® as one of the top medical device consulting firms. We’lll help you navigate the medical device consulting difficulties associated with new product submissions. Regulatory Compliance Associates® medical device consulting company has expertise in both the approval process and post-approval support.

- New Product Approval

- Post-Approval Support

- Outsourced Staffing

- EU MDR

- Combination Products

Compliance Assurance

Increasingly, life science companies are feeling the pressure of greater scrutiny by regulators, and responding by developing sustainable compliance strategies. Whether it’s preparing for an audit, developing a response to an FDA finding, or remediation to an adverse event, Regulatory Compliance Associates® can help.

Our network of over 500 medical device consultant & FDA, MHRA & EMA veterans are industry professionals offers a unique blend of expertise. This allows Regulatory Compliance Associates® to handle both simple and complex regulatory compliance challenges within medical device consulting companies.

- Gap Assessments

- Internal Audits

- Employee Training

- Notified Body Response

- Data Integrity

Quality Assurance

Regulatory Compliance Associates® is globally reknown for quality assurance services, including quality system assessments, strategy, implementations, and quality metrics to ensure continuous improvement. Each Regulatory Compliance Associates® medical device consultant is a quality expert with experience spanning major corporations and start-ups. RCA’s quality assurance services experts know firsthand how to achieve, maintain, and improve quality, and we excel in transferring this knowledge to your organization.

In the medical devices field, quality assurance (QA) is more than merely ensuring the quality of a finished product. You need the tools to monitor and regulate every process from the design of a new product to continued quality compliance as the device is sent to market. At Regulatory Compliance Associates®, we offer you the quality assurance services you need to monitor these processes and ensure quality compliance every step of the way.

With more than 20 years experience working with medical device consulting companies, Regulatory Compliance Associates® trusted medical device quality assurance consultant team is fully equipped to handle your unique QA needs.

- ISO13485

- 21 CFR 210

- 21 CFR 211

- Outsourced Staffing

- MDSAP

- Facility Validation

- Equipment Validation

- Quality Metrics

Remediation Services

Regulatory Compliance Associates® is widely recognized within medical device consulting companies & the life science industry for our remediation services & support. Regulatory Compliance Associates® ability to help companies successfully resolve complex regulatory challenges have a proven track record of success. Our medical device consulting services include significant experience with the development of responses to 483 Observations, Warning Letters, Untitled Letters and Consent Decrees.

- Regulatory Action

- Regulatory Compliance

- Regulatory Enforcement

- Warning Letter

- 483 Observation

- Oversight Services

Our value goes beyond the initial response by helping companies successfully execute their action plans, develop an improved compliance culture tailored to the needs of their business, and ultimately move beyond the regulatory action to emerge as a stronger business. We negotiate difficult demands of remediation with insight and the clear advantage of our medical device consultant expertise and experience that makes partnering with Regulatory Compliance Associates® a competitive differentiator in the remediation space.

- Quality System

- Technical File

- Design History File

- Data Integrity

- cGMP

Strategic Consulting

Whether it’s a strategy, a technical plan, or project, Regulatory Compliance Associates® medical device consultancy can help ensure a successful project. Regulatory Compliance Associates® due diligence consulting can deliver your project on time, on budget, and you’re never embroiled in a costly mistake.

Our medical device consultant Experts are industry Experts are here to provide the unique insight you need before an M&A deal, through a staffing crisis and in every area of your product’s development and life cycle. As the trusted medical device manufacturing consultants of thousands of companies around the world, we have the knowledge and expertise needed to deliver exceptional results to your business — no matter your size or unique needs.

- Manufacturing Optimization

- Product Lifecycle Management

- Mergers & Acquisitions (M&A)

- Due Diligence

- Device Vigilance

- Risk Management Plan

- Product Complaints

- Medical Information

About Regulatory Compliance Associates

Regulatory Compliance Associates® (RCA) provides medical device consulting to the following industries for resolution of life science challenges:

Regulatory Compliance Associates® (RCA) provides medical device consulting to the following industries for resolution of life science challenges:

- Life Sciences

- Pharmaceutical

- Biologic & Biotechnology

- Sterile compounding

- Medical device

- Lab Testing

We understand the complexities of running a life science business and possess areas of expertise that include every facet of R&D, operations, regulatory affairs, quality, and manufacturing. We are used to working on the front lines and thriving in the scrutiny of FDA, Health Canada, MHRA and globally-regulated companies.

As your partners, Regulatory Compliance Associates can negotiate the potential minefield of regulatory compliance and regulatory due diligence with insight, hindsight, and the clear advantage of our unique expertise and experience.

- Founded in 2000

- Headquartered in Wisconsin (USA)

- Expertise backed by over 500 industry subject matter experts

- Acquired by Sotera Health in 2021

About Sotera Health

The name Sotera Health was inspired by Soteria, the Greek goddess of safety, and reflects the Company’s unwavering commitment to its mission, Safeguarding Global Health®.

Sotera Health Company, along with its three best-in-class businesses – Sterigenics®, Nordion® and Nelson Labs®, is a leading global provider of mission-critical end-to-end sterilization solutions and lab testing and advisory services for the healthcare industry. With a combined tenure across our businesses of nearly 200 years and our industry-recognized scientific and technological expertise, we help to ensure the safety of over 190 million patients and healthcare practitioners around the world every year.

We are a trusted partner to more than 5,800 customers in over 50 countries, including 40 of the top 50 medical device companies and 8 of the top 10 pharmaceutical companies.

Commitment to Quality

Our Certificate of Registration demonstrates that our Quality Management System meets the requirements of ISO 9001:2015, an internationally recognized standard of quality.

To begin the Regulatory Compliance Associates® scoping process today, please enter your information in the blue form below and click the submit button at the bottom of the webpage.